👋 Exciting news! UPI payments are now available in India! Sign up now →

Operating costs in cost accounting: Definition, formula and examples

Operating costs are a fundamental concept in cost accounting, representing the expenses incurred to maintain a business’s day-to-day operations. These costs are essential for evaluating a company's financial health and operational efficiency.

By tracking and analyzing operating cost in business, businesses can identify areas for cost optimization, enhance profitability, and ensure long-term sustainability. Operating costs typically include fixed costs, such as rent and salaries, and variable costs, like raw materials and utilities, which fluctuate with production levels.

Understanding how to calculate these expenses through established formulas allows businesses to budget effectively and make informed decisions. Whether you’re a business owner or a financial professional, mastering the principles of operating costs will give you the tools to improve cost management and drive strategic success.

What are operating costs in cost accounting?

Operating costs in cost accounting refer to the expenses a business incurs to carry out its core operations. These costs are directly tied to the production of goods or services and the maintenance of daily business activities.

Operating costs are broadly classified into two categories:

● Fixed costs: These are constant expenses that do not change with production levels, such as rent, insurance, and employee salaries.

● Variable costs: These fluctuate with production or sales volume, including costs of raw materials, utilities, and shipping.

Operating expenses do not include non-operational costs such as financing charges or losses from investments. Monitoring these expenses is crucial for grasping a company's profitability and operational efficiency.

Precise computation and scrutiny of operating costs enable businesses to pinpoint inefficiencies, establish suitable pricing strategies, and undertake informed decisions to improve their performance and competitive edge.

Why do you need an in-depth understanding of operating costs?

Operating costs are central to a company’s financial management and operational efficiency. Gaining an in-depth understanding of the operating cost in business empowers organizations to navigate complex financial landscapes, optimize operations, and make strategic decisions.

Below, we explore the key reasons why such knowledge is essential, addressing its importance across financial health, cost management, strategic decision-making, risk management, benchmarking, stakeholder communication, and sustainability.

Financial health

Operating costs are a direct reflection of a company’s financial health, influencing profitability and the ability to allocate resources effectively.

● Profitability analysis

By analyzing operating costs, businesses can determine their break-even point and assess whether their current pricing and sales volumes support profitability.

Understanding the balance between revenues and operating expenses ensures that resources are being used efficiently to drive profits.

● Budgeting

An accurate grasp of operating costs enables businesses to create realistic budgets. Budgeting helps allocate resources effectively, avoiding overspending and ensuring funds are available for critical operations.

Businesses can use historical operating cost data to forecast future expenses, ensuring long-term stability and growth.

Cost management

Effective cost management is crucial for maintaining competitive pricing and maximizing margins. Understanding operating costs lays the groundwork for comprehensive cost control strategies.

● Cost analysis

A detailed breakdown of operating costs allows businesses to identify cost drivers—specific factors that influence expenses.

By categorizing and analyzing these costs, businesses can pinpoint inefficiencies, such as unnecessary expenditures or excessive supplier charges, and address them.

● Cost reduction

Once inefficiencies are identified, businesses can implement targeted cost-cutting measures. These may include negotiating better supplier contracts, optimizing resource utilization, or adopting energy-efficient technologies.

Reducing the operating cost in business without compromising quality enhances the overall profitability and competitiveness of the organization.

Strategic decision-making

In-depth knowledge of operating costs is a cornerstone for strategic business decisions that drive growth and adaptability.

● Pricing strategies

Understanding operating costs allows businesses to set prices that cover all expenses while ensuring profitability.

Whether adopting cost-plus pricing or value-based pricing, accurate knowledge of operating costs ensures that the pricing strategy aligns with market conditions and profitability goals.

● Investing strategies

Decisions about expansion, new product lines, or technological investments often hinge on operating cost analysis.

For instance, investing in automation might involve high upfront costs but lead to long-term savings in labor and operational expenses. An in-depth understanding ensures such decisions are data-driven and financially sound.

Risk management

Operating cost analysis plays a significant role in mitigating financial risks and ensuring the organization remains resilient under changing conditions.

● Financial forecasting

Accurate forecasting of operating costs in cost accounting enables businesses to anticipate financial needs and prepare for potential challenges.

By predicting future expenses, businesses can avoid cash flow crises and ensure the availability of resources for sustained operations.

● Financial readiness

A thorough understanding of operating costs helps build contingency plans, ensuring the organization is financially prepared for unexpected downturns or industry shifts.

Proactive management of these costs can prevent businesses from falling into debt or losing market share during crises.

Benchmarking

Benchmarking involves comparing operating costs to internal targets or industry standards to evaluate performance and identify opportunities for improvement.

● Performance measurement

Tracking and analyzing operating costs over time provides valuable insights into a business’s operational efficiency. Comparing current expenses against historical data helps measure improvement and spot trends that require corrective action.

● Industry-standard measurement

Benchmarking against competitors or industry averages reveals whether a business is operating efficiently. For example, if a company’s energy costs significantly exceed the industry norm, it can investigate and implement energy-saving measures to align with best practices.

Stakeholder communication

Transparent communication about operating costs strengthens relationships with internal and external stakeholders, fostering trust and collaboration.

● Transparent communication

Detailed knowledge of operating costs enables businesses to provide stakeholders—such as investors, lenders, and partners—with clear and accurate financial information. Transparency builds trust and assures stakeholders of the company’s operational competence.

● Detailed reporting

Regular, detailed reports on operating costs demonstrate accountability and provide a comprehensive view of the company’s financial performance. Stakeholders can use this information to assess the company’s health and make informed decisions about their level of involvement.

Sustainability

Operating cost management is increasingly tied to a company’s sustainability efforts, as businesses strive to comply with regulations and adapt to societal and environmental changes.

● Regulatory compliance

Governments and industry bodies often impose regulations that impact operating costs, such as environmental taxes or energy-efficiency requirements. Understanding these costs allows businesses to plan for compliance and avoid penalties.

● Change adoption

Sustainability-focused businesses often aim to reduce waste and carbon footprints. Identifying high-cost or high-impact areas enables companies to adapt their operations to align with these goals. For instance, investing in renewable energy sources may reduce long-term energy costs while enhancing sustainability credentials.

What are the 5 fundamental components of operating costs?

Operating costs consist of various expense categories essential to the functioning of a business.

A clear understanding of these components helps organizations calculate operating cost accurately, allocate resources efficiently, optimize spending, and maintain profitability.

Here are the five fundamental components of operating costs:

Direct costs

Among the most significant components are direct costs, which are expenses that can be directly traced to the production of goods or services.

These costs typically vary with production levels and include items such as raw materials, wages for production workers, and supplies used specifically for manufacturing.

Direct costs play a central role in calculating the cost of goods sold and setting accurate pricing to maintain profitability.

Indirect costs

Indirect costs, in contrast, are not directly attributable to a specific product or service but are vital for the overall functioning of a business. Such expenses encompass utilities, administrative wages, and the upkeep of facilities and equipment.

Although they are not directly associated with production, these costs are instrumental in the company's efficient operation and necessitate careful management to maintain control over total expenditures.

Fixed costs

Fixed costs remain constant regardless of the company’s production levels, providing a degree of stability in financial planning. These costs include expenses like rent, insurance, and depreciation of fixed assets.

Fixed costs are predictable, making them easier to budget for and manage over the long term, even as production volumes fluctuate.

Variable costs

Variable costs, in contrast, change in proportion to production or sales levels. Examples of variable costs include the expenses for raw materials, shipping, and sales commissions.

As production scales up or down, variable costs follow suit, making their monitoring critical to ensuring profitability as businesses expand or contract operations.

Semi-variable costs

Semi-variable costs combine elements of both fixed and variable costs. These expenses have a consistent base amount, but portions of them vary with usage or production levels.

For instance, utility bills may include a fixed base charge along with a variable component based on usage, while salaries may involve a fixed portion with additional costs incurred for overtime.

Understanding this kind of operating cost in business is particularly useful during periods of fluctuating activity, as it helps predict changes in expenses more accurately.

Fixed costs vs. variable costs

Fixed costs and variable costs are two fundamental components of operating cost in business and play crucial roles in financial management.

While both contribute to a company's overall expenses, their characteristics, behavior, and impact differ significantly. Understanding these differences is vital for effective cost management, budgeting, and decision-making.

Below is an in-depth analysis of how these two cost types differ across various aspects.

1. Definition

● Fixed costs

The nature of fixed costs is stable and predictable. These expenses are contractual or time-based and often reflect long-term commitments. They are considered necessary for the business to maintain its infrastructure and basic operations.

● Variable costs

Variable costs are dynamic and fluctuate based on business output. Their nature is activity-dependent, meaning that they only arise when production or sales activity occurs. These costs are essential for the production process but are not incurred when operations halt.

2. Nature

● Fixed costs

Fixed costs are typically categorized as overhead expenses and appear on the financial statements under operating expenses.

Because they do not vary with production, they contribute to a company’s break-even point and are essential for determining profitability at different production levels.

● Variable costs

Variable costs are included in the cost of goods sold (COGS) on the income statement. They directly affect gross profit and net income since they fluctuate with revenue. Higher production or sales volumes lead to higher variable costs, which impact profit margins.

3. Impact on financial statement

● Fixed costs

Fixed operating costs in cost accounting are typically categorized as overhead expenses and appear on the financial statements under operating expenses.

Because they do not vary with production, they contribute to a company’s break-even point and are essential for determining profitability at different production levels.

● Variable costs

Variable costs are included in the cost of goods sold (COGS) on the income statement. They directly affect gross profit and net income since they fluctuate with revenue. Higher production or sales volumes lead to higher variable costs, which impact profit margins.

4. Behavior with production level

● Fixed costs

Fixed costs are constant and do not vary with the level of production. For example, factory rent is due regardless of whether the facility is producing at maximum capacity or not at all.

As the volume of production rises, the fixed cost per unit diminishes since the same total cost is distributed over a larger number of units.

● Variable costs

Variable costs are directly proportional to the levels of production. Should production increase twofold, variable costs will do the same, as additional resources are necessary for the production of extra units. This direct relationship maintains the consistency of variable costs on a per-unit basis.

5. Cash flow impact

● Fixed costs

Fixed costs have a predictable impact on cash flow since they do not change over time. This consistency can be advantageous for planning but may strain cash flow during periods of low revenue, as these costs must be paid regardless of income.

● Variable costs

Variable costs have a flexible impact on cash flow, increasing or decreasing in line with business activity. During times of low production, these costs naturally reduce, easing the pressure on cash flow.

However, during high production, the increase in variable costs must be carefully managed to avoid cash flow shortages.

6. Treatment

● Fixed costs

Fixed costs are typically treated as period costs and are allocated to time periods rather than individual products. For example, depreciation on a factory building is spread evenly over its useful life, regardless of production levels.

● Variable costs

Variable costs are treated as product costs because they are directly associated with the production of goods or services. These costs are allocated to each unit produced, making them a key component of calculating cost per unit.

7. Level of flexibility

● Fixed costs

Fixed costs are inflexible in the short term due to their contractual or structural nature. For example, lease agreements or employee salaries cannot be adjusted quickly without renegotiation or significant changes to the business structure.

● Variable costs

Variable costs offer greater flexibility, as they can be adjusted quickly in response to production needs. Businesses can control these costs by scaling production up or down, sourcing cheaper raw materials, or optimizing usage.

8. Timing of expense recognition

● Fixed costs

Fixed costs are recognized in financial statements periodically, often on a monthly or annual basis, regardless of production levels. For instance, rent is recognized as a recurring expense or fixed operating cost in business every month, irrespective of the level of activity in the facility.

● Variable costs

Variable costs are recognized as expenses when the related production or sales occur. For example, the cost of raw materials is recorded only when the materials are used in production. This timing ensures that expenses align with revenue generation.

9. Example

● Fixed costs

Fixed costs are expenses like office space rent, insurance premiums, full-time employees' salaries, equipment depreciation, and long-term leases. These costs stay the same over a certain period and are crucial for business continuity.

● Variable costs

Variable costs, on the other hand, include items such as raw materials, packaging, utilities that change with production levels, hourly wages, and sales commissions.

These expenses vary with the level of business operations and constitute a significant portion of production costs.

What are the types of operating costs?

Operating costs include the expenses essential for managing a business's daily functions and sustaining its primary activities. They are vital for financial management, analyzing profitability, and making decisions.

Generally, operating costs in cost accounting are categorized into Operating Expenses and Cost of Goods Sold (COGS), with each category encompassing distinct types of expenses that add to the total cost structure.

Operating expenses

Operating expenses are the recurring costs associated with managing a business's daily activities that are not directly linked to producing goods or services. These expenses are essential for supporting administrative, marketing, and overall operational processes.

● Selling & marketing expenses

These costs cover the expenses associated with promoting and selling a company's products or services. They encompass advertising campaigns, digital marketing expenditures, sales team wages, and promotional events.

These expenses are vital for business growth as they seek to increase revenue by attracting and retaining customers.

● General and administrative expenses

Administrative expenses cover costs related to managing the overall operations of a company. This includes executive salaries, office supplies, utilities for office spaces, and software subscriptions for administrative functions.

These expenses are crucial for ensuring that business operations run smoothly and efficiently.

● Accounting and legal expenses

Operating costs in cost accounting and the legal context are typically associated with maintaining accurate financial records, tax compliance, and legal matters.

Businesses often hire accountants and legal professionals or engage firms to handle audits, file taxes, ensure regulatory compliance, and manage contracts or disputes.

● Research & development expenses

R&D expenses are incurred to innovate, improve products, or develop new offerings. These costs include salaries of R&D teams, costs of prototype creation, laboratory expenses, and technology used for innovation.

Businesses in tech, pharmaceuticals, and manufacturing often incur significant R&D costs to stay competitive.

● Depreciation & amortization

Depreciation is the gradual decrease in the value of physical assets such as machinery or buildings, whereas amortization pertains to intangible assets like patents. Both are non-cash expenses that represent the deterioration and eventual obsolescence of assets over time.

Depreciation and amortization are essential for precise financial reporting and effective budgeting.

● Interest expenses

An operating cost in business, in cases of interest-related expenditures, arises from borrowing funds, such as interest payments on loans, credit lines, or bonds.

These expenses represent the cost of capital and are particularly important for businesses relying on any form of debt or credit-based financing for operations or expansion.

● Insurance premiums

Insurance costs cover protection against risks related to any kind of property damage, liability, theft, or employee-related claims.

Businesses must often pay premiums for various policies, including general liability insurance, worker’s compensation, and business interruption insurance, to safeguard their operations.

● Inventory & rent

The cost of maintaining inventory, including storage and warehousing, is a significant operating expense in business. Additionally, rent expenses for office spaces, retail outlets, or warehouses fall under this category of operating expenses.

These costs can be fixed or semi-variable, depending on the nature and particular details of the lease as well as inventory requirements.

COGS (Cost of Goods Sold)

The cost of goods sold (COGS) encompasses all direct expenses involved in the production or delivery of a business's products or services. These costs are closely tied to the manufacturing or service delivery process and vary directly with the level of production or sales activity.

Accurately calculating COGS is essential for determining gross profit and assessing the profitability of a company’s offerings. Below are the major components of COGS:

● Direct labor cost

Direct labor costs include wages paid to employees directly involved in production, such as assembly line workers or machine operators. These costs are variable and scale with production levels, making them a vital component of COGS.

● Raw materials cost

Raw materials are the basic inputs required to manufacture goods. Depending on the industry, these could include items such as fabric for apparel, lumber for furniture, or chemicals for pharmaceuticals.

The cost of raw materials can vary significantly based on market conditions, supplier pricing, and production demands. This variability makes raw material costs a vital and dynamic component of COGS as well as the operating cost formula as a whole.

● Rent of manufacturing unit

Rent for facilities used in production, such as factories or workshops, is an integral part of COGS. While rent is typically a fixed cost, it is directly associated with manufacturing and therefore categorized under COGS rather than general operating expenses.

● Utility costs of manufacturing unit

Utilities used in the manufacturing process, such as electricity, gas, and water, are another significant aspect of COGS.

These utility costs can include powering production equipment, heating or cooling the production area, and maintaining environmental conditions for sensitive goods.

Utility expenses often vary with production levels, making them semi-variable and an important element to monitor closely.

● GST tax of manufacturing unit

Production-related levies, such as the Goods and Services Tax (GST), are tied directly to the manufacturing process.

They are applied to services rendered and goods produced, making their inclusion in COGS essential for accurate profitability and pricing analysis.

● Equipment repair costs

The repair and maintenance of machinery and tools used in production are key to ensuring smooth and efficient manufacturing processes.

Costs for servicing, spare parts, and emergency repairs fall under COGS because they are essential for maintaining production capability.

Without regular maintenance, equipment failure could disrupt production and lead to higher costs in the long run.

Steps to calculate operating costs

Identify your cost categories

Calculating operating costs begins with identifying all expense categories necessary for running a business. These costs are generally categorized into three groups: fixed, variable, and semi-variable.

Fixed costs do not change with production levels, variable costs vary with business activity, and semi-variable costs have elements of both.

Examples of these costs are rent, salaries, utilities, raw materials, and marketing expenses. Proper categorization is crucial for precise calculations and efficient cost control.

Gather financial data

Once the cost categories are identified, gather comprehensive financial data for a specified period—monthly, quarterly, or annually. This data can be obtained from accounting software, invoices, contracts, and financial statements.

Ensure that all relevant expense details are included, such as supplier payments, employee salaries, and utility bills. Accurate and complete data collection minimizes errors and ensures a reliable analysis of operating costs.

Calculate your fixed costs

Fixed costs refer to expenses that stay the same, irrespective of the business's production or sales levels.

Start by pinpointing all costs that remain unchanged during the specified period. Such costs often encompass facility rent, insurance premiums, permanent staff salaries, and depreciation of assets.

After identifying these costs, tally them to determine the total fixed costs. For example, if your monthly rent is $2,000 and your annual insurance costs are $10,000, your total fixed costs for the year would be $34,000.

Calculate your variable costs

Variable costs vary directly with production or sales volumes, increasing or decreasing as activity levels change. To calculate these costs, one must identify all expenses that vary with production, such as raw materials, commissions, and energy used in manufacturing.

When you calculate operating cost, these expenses should be totaled over a given period to determine the overall variable costs. For instance, if the cost of raw materials varies monthly with production levels, these costs should be added together to find the total variable costs for that period.

Calculate your semi-variable costs

Semi-variable costs include both fixed and variable elements. Identify expenses such as utility bills with a base fee (fixed component) and usage-based charges (variable component) or salaries with fixed pay and overtime allowances.

Separate the fixed portion of these costs from the variable portion, then sum them up. For example, if your monthly electricity bill includes a fixed charge of $200 plus $0.10 per kilowatt-hour used, calculate the total by combining the fixed fee with the variable usage cost.

Calculate total operating costs

To calculate the total operating costs, use the following operating cost formula.

Total Operating Costs = Fixed Costs + Variable Costs + Semi-Variable Costs

Add together the totals from the previous calculations to derive the overall operating costs for the chosen period. This total represents the expenses incurred to maintain daily business operations and provides a foundation for financial analysis and planning.

Analyze the results

After implementing the operating cost formula and calculating the total costs, analyze the results to gain insights into your company’s financial health. Assess which categories of costs are consuming the largest portion of resources.

For instance, high variable costs might indicate inefficiencies in production, while increasing fixed costs could highlight overcommitments to long-term contracts or infrastructure. Comparing these costs against revenue helps determine profitability and operational efficiency.

Measure key performance indicators

Use the calculated operating costs to measure key performance indicators (KPIs) that reflect the company’s financial performance. Common KPIs include the Operating Expense Ratio (OER), which is calculated as:

OER = (Operating Costs / Revenue) × 100

This ratio indicates how efficiently the company is using its resources to generate revenue. A lower OER signifies better cost control and operational efficiency.

Other relevant KPIs might include gross profit margins and operating profit margins, which provide additional insights into profitability.

Review and adjust accordingly

Once you’ve calculated your operating costs in cost accounting, it’s important to periodically review them and make adjustments as needed.

Analyze the data to identify potential areas for cost reduction, such as renegotiating contracts, implementing energy-saving practices, or improving operational efficiencies. Evaluate whether current spending aligns with business goals and performance metrics.

Regular monitoring ensures that your cost structure remains adaptable to market changes and helps maintain financial stability over time. Continuous refinement of your operating costs can lead to better resource allocation and sustained profitability.

How to calculate operating costs?

Calculating operating costs involves identifying and categorizing expenses into fixed, variable, and semi-variable costs.

Fixed costs, including rent and insurance, stay unchanged regardless of production levels. Variable costs, like raw materials and utilities, vary with production volume. Semi-variable costs, such as electricity bills that have a fixed charge and a usage-based component, incorporate elements of both.

The calculation of operating cost formula works the following way:

Operating Costs = Fixed Costs + Variable Costs + Semi-Variable Costs

Example: If fixed costs (rent, insurance) total $50,000, variable costs (materials, utilities) are $30,000, and semi-variable costs (electricity) are $5,000, then the total operating costs are:

50,000 + 30,000 + 5,000 = 85,000

This represents the expenses required to run the business.

Impact of external factors on operating costs of your business

Operating costs, which include both fixed and variable expenses, are not solely influenced by internal business decisions. External factors can significantly affect the cost structure, posing challenges or offering opportunities for businesses to adapt and optimize operations.

Economic conditions

Economic conditions, such as inflation, recession, or economic growth, have a direct influence on operating cost in business.

During periods of inflation, the cost of raw materials, utilities, and labor tends to rise, increasing variable costs. Conversely, in a recession, businesses may face declining demand but still incur fixed costs, such as rent and salaries, creating financial strain.

Economic growth may increase operating costs due to higher competition for resources, but it can also lead to increased revenue, helping offset these costs. Maintaining flexibility in budgeting and adopting cost-saving measures is crucial to navigating economic fluctuations.

Regulatory changes

Regulatory changes often affect operating costs significantly. For instance, stricter labor laws may increase payroll expenses, while new environmental regulations may require businesses to invest in eco-friendly equipment or processes, raising both fixed and variable costs.

Tax reforms or changes in tariffs can also impact expenses. Non-compliance with regulations can lead to penalties, further increasing costs. Businesses must stay informed about regulatory developments and allocate resources for compliance to avoid unexpected financial burdens.

Market comparison

Competitor pricing and market trends play a key role in influencing operating costs. If competitors lower their prices, businesses may need to cut their costs to remain competitive.

Conversely, if competitors invest in advanced technology or expand operations, businesses might face pressure to match those investments, increasing their expenses.

Benchmarking operating costs against industry standards helps identify areas of inefficiency and informs strategic adjustments to maintain a competitive edge.

Supply chain disruptions

Disruptions in the supply chain can significantly escalate operating cost in business. Delays, shortages, or rising transportation costs can increase the expense of acquiring raw materials or delivering goods.

For instance, a fuel price hike may lead to higher logistics costs, while global disruptions, such as pandemics or natural disasters, can create bottlenecks in the supply chain. Diversifying suppliers, adopting inventory management tools, and investing in local sourcing are strategies businesses can use to mitigate these risks.

Technological changes

Technological advancements often require businesses to upgrade systems or equipment, impacting operating costs.

While these upgrades might involve high initial costs, such as purchasing automation tools or adopting new software, they often lead to long-term savings by improving efficiency and reducing labor expenses.

Businesses that fail to keep pace with technological changes risk falling behind competitors, which could indirectly increase costs through lost opportunities or reduced market share.

Geopolitical factors

Geopolitical factors, including trade wars, international conflicts, and changing trade agreements, can affect operating costs in multiple ways. For instance, increased tariffs on imported goods can raise material costs, while sanctions might limit access to certain suppliers or markets.

Currency fluctuations due to political instability can also impact costs for businesses involved in international trade. Proactively assessing geopolitical risks and developing contingency plans are essential to mitigating their impact.

Financing costs

The cost of financing, such as interest rates on loans or credit, is another external factor affecting operating costs. An increase in interest rates can raise borrowing costs, impacting businesses that rely on debt for operational or expansion needs.

Similarly, limited access to affordable financing during economic downturns can strain cash flow and force businesses to reassess spending priorities. Maintaining strong financial health and exploring alternative financing options, like equity funding, can help mitigate these challenges.

Steps to manage the operating costs of your business

Managing operating costs is essential for maintaining profitability and financial stability in any business. Effective cost management ensures resources are used efficiently, unnecessary expenses are eliminated, and the business remains competitive.

Below are the key steps involved in managing operating costs successfully.

1. Conduct cost analysis

The first step in managing operating costs in cost accounting is conducting a thorough cost analysis. This involves examining all business expenses to understand where the money is being spent.

Break down costs into categories such as fixed, variable, and semi-variable, and assess their impact on overall profitability. By identifying high-cost areas or inefficiencies, businesses can gain insights into where adjustments are needed.

2. Identify cost drivers

Cost drivers are the key factors that heavily influence a business’s operating expenses. For example, in a manufacturing company, these might include labor, raw materials, or energy consumption.

Identifying these primary cost contributors allows businesses to concentrate their efforts on areas with the greatest impact, making it possible to implement targeted cost-saving strategies without disrupting essential operations.

3. Involve key stakeholders

Successful cost management involves collaboration among various teams and departments. Engaging key stakeholders, such as department heads, managers, and financial professionals, ensures a comprehensive view of operating costs.

This collaborative approach fosters accountability, generates innovative cost-reduction ideas, and helps build consensus for implementing cost-saving initiatives across the organization.

4. Conduct cost estimation

Cost estimation involves forecasting future expenses based on historical data, industry trends, and projected business activities. Accurate cost estimation helps businesses anticipate changes in expenses and align them with revenue expectations.

For example, if production is expected to increase, estimating the corresponding rise in raw material and labor costs ensures preparedness.

5. Develop a budget

After analyzing and estimating costs, develop a comprehensive budget to guide financial decision-making. Allocate funds for essential operations while setting limits on discretionary spending.

A well-structured budget serves as a roadmap, helping businesses stay aligned with their financial goals. Regularly updating the budget ensures it reflects current business conditions and market realities.

6. Setup a cost control strategy

A cost control strategy involves implementing processes to monitor and manage expenses proactively.

Establishing controls such as approval protocols for purchases, vendor negotiations, and tracking systems for inventory and utilities can help prevent unnecessary spending. Automating processes like invoice management or expense tracking also improves efficiency and reduces errors.

7. Perform variance analysis

Variance analysis involves comparing actual expenses to the budgeted amounts to identify discrepancies.

For example, if utility costs exceed the budget, it may indicate inefficiencies or increased usage. Regular variance analysis allows businesses to understand the reasons behind cost overruns and address them promptly.

8. Implement corrective actions

When discrepancies or inefficiencies are detected, timely corrective measures are essential to bring costs back under control. These measures may involve renegotiating terms with suppliers, improving energy efficiency, or optimizing workflows to reduce redundancy.

Addressing issues quickly helps mitigate the impact of overspending and ensures that financial objectives remain on track.

9. Review and adjust accordingly

Managing operating costs is an ongoing process that requires regular review and adjustments.

Periodically reassess cost structures, analyze market conditions, and evaluate the effectiveness of cost-control measures. This also makes it easier to calculate operating cost given metrics are always kept updated.

Adapting to changing business environments ensures that cost management strategies remain relevant and effective. For example, adopting new technologies or adjusting budgets to reflect rising raw material prices can help the business stay competitive.

Operating costs vs. SG&A expenses

Operating costs and Selling, General, and Administrative (SG&A) expenses are two fundamental concepts in cost accounting and financial management.

Both play critical roles in understanding a business’s expense structure, but they differ significantly in definition, components, nature, and strategic importance.

Below, we provide an in-depth comparison to help clarify their differences and importance in financial decision-making.

Definition

● Operating costs

Operating costs in cost accounting represent the total expenses required to manage a business’s daily operations.

These costs encompass direct costs, which are specifically linked to production activities, and indirect costs, which facilitate general operational support. They are fundamental to ensuring the smooth functioning of the business and the delivery of goods or services.

● SG&A expenses

Selling, General, and Administrative (SG&A) expenses cover the costs related to a company’s overall management, administrative tasks, and sales and marketing efforts.

Unlike operating costs tied directly to production, SG&A expenses focus on maintaining the business infrastructure and promoting revenue generation through branding and sales initiatives. These expenses are essential for sustaining the organization’s non-production functions.

Components

● Operating costs

Operating costs can be divided into two primary categories:

-Direct costs: These are expenses directly associated with the creation of goods or delivery of services, such as raw materials, wages for production workers, and utilities used in manufacturing.

-Indirect costs: These are general expenses that support overall business operations but are not linked to specific products, including items like rent, general utility bills, and facility maintenance.

● SG&A expenses

SG&A expenses are primarily composed of:

-Selling costs: Expenses for marketing, advertising, and commissions for sales staff.

-General and administrative costs: Expenses for office management, salaries of administrative staff, and legal and accounting services.

Nature

● Operating costs

The nature of operating costs in cost accounting is broad, covering all expenses necessary to keep the business functional. These costs can be variable, fluctuating with production levels (e.g., raw materials), or fixed, remaining constant regardless of output (e.g., rent).

● SG&A expenses

SG&A expenses are primarily fixed and do not vary with production levels. They encompass costs essential for business operations but are not directly related to manufacturing or service delivery. Examples include office rent and executive salaries.

Direct relation to production

● Operating costs

The operating cost in business has a direct connection to production activities. Costs like raw materials, utilities for production facilities, and labor wages for factory workers are essential for creating goods or services.

● SG&A expenses

SG&A expenses do not have a direct link to production. Instead, they focus on supporting activities such as sales, administration, and corporate governance. For example, advertising campaigns and management salaries are unrelated to the physical production process.

Impact on financial statement

● Operating costs

Operating costs appear in multiple areas of the financial statement. Direct costs are listed under Cost of Goods Sold (COGS) on the income statement, directly impacting gross profit. Indirect costs are included in the operating expenses section, affecting operating profit and net income.

● SG&A expenses

SG&A expenses are reported under operating expenses on the income statement but are separate from COGS. They impact operating profit and net income but do not influence gross profit directly. This segregation allows businesses to evaluate the efficiency of their administrative and sales functions separately from production.

Time-frame

● Operating costs

Operating costs are usually short-term in nature, incurred during daily business operations. These costs are cyclical and vary based on production schedules, sales activities, or business output.

● SG&A expenses

SG&A expenses exhibit consistency over time, typically involving long-term commitments such as salaries for administrative staff, office leases, and recurring marketing strategies. This stability enables businesses to plan and forecast SG&A expenses with greater predictability.

Accounting treatment

● Operating costs

Operating costs are split into direct and indirect categories for accounting purposes. Direct costs are recorded as part of COGS, while indirect costs are accounted for as operating expenses. These costs are matched to revenues in the same accounting period to reflect the cost of producing goods or services sold.

● SG&A expenses

SG&A expenses are treated as period costs in accounting, meaning they are expensed in the period they are incurred. They are not allocated to specific products or services but are reported as part of the company’s operating expenses.

Strategic importance

● Operating costs

Effective management of operating expenses is crucial for sustaining profitability. Minimizing production inefficiencies and securing more favorable prices for raw materials can result in substantial cost reductions.

Furthermore, operating expenses affect a business's ability to scale, as they dictate the economic viability of expanding production capabilities.

● SG&A expenses

SG&A expenses are strategically important for business growth and market positioning. Investments in advertising, branding, and sales teams drive revenue, while administrative expenses ensure smooth operations.

Managing SG&A effectively is key to balancing overhead costs with the benefits they bring in terms of revenue generation and operational stability.

Influence on pricing

● Operating costs

Operating costs play a direct role in pricing decisions. Businesses must set prices that cover both fixed and variable operating costs while leaving room for a reasonable profit margin. Underpricing may lead to losses while overpricing could reduce competitiveness.

● SG&A expenses

SG&A expenses influence pricing indirectly by determining the company’s overall cost structure. High SG&A expenses may push businesses to set higher prices to achieve profitability, especially if administrative or sales expenses are a significant portion of total costs.

Example

● Operating costs

Consider a clothing manufacturer. Its operating costs would include the cost of raw materials like fabric, wages for factory workers, electricity to power machines, and rent for the manufacturing facility. These expenses are tied to the production and delivery of the final product.

● SG&A expenses

For the same clothing manufacturer, SG&A expenses would include salaries for office staff, advertising campaigns for new product lines, legal fees for contracts, and rent for the corporate office. These costs are unrelated to production but essential for managing the business and driving sales.

Operating expenses and operating costs: What’s the difference?

Operating expenses and operating costs in cost accounting are related but not identical concepts in financial management.

Operating costs refer to all expenses incurred to keep a business running, including both direct costs (like raw materials and direct labor) and indirect costs (like rent and utilities). These costs include everything required to produce goods or services and sustain day-to-day operations.

In contrast, operating expenses (OPEX) refer to the costs related to the daily functioning of a business that are not directly tied to the production of goods or services. These expenses include Selling, General, and Administrative (SG&A) costs such as marketing, office rent, executive salaries, legal fees, and insurance.

Example: Consider a furniture manufacturing company.

● Operating costs: The cost of wood, wages for factory workers, electricity used in the factory, and machinery maintenance—all directly tied to production.

● Operating expenses: Salaries of office staff, advertising campaigns, rent for the corporate office, and legal fees—costs needed to run the business but not related to producing furniture.

In short, operating costs cover both production-related and general business expenses, while operating expenses focus only on non-production costs essential for business operations.

What are the risks of cutting operating costs?

While cutting operating costs may seem like an effective way to improve profitability and financial stability, it carries significant risks if not done strategically.

Reducing costs without proper evaluation can harm long-term growth, employee satisfaction, and overall business performance.

Here are the key risks associated with cutting operating costs:

Reduced innovation

Reducing operating expenses frequently impacts the budgets allocated for research and development (R&D) or the investment in emerging technologies.

When companies cut back on innovation expenditure, they run the risk of lagging behind competitors who maintain or increase their investment in product development, process enhancements, or cutting-edge technologies.

This shortfall in innovation can eventually impair a company's capacity to adjust to market shifts, satisfy changing customer needs, and capitalize on new business opportunities.

For instance, a technology firm that curtails its R&D budget might find it challenging to introduce new products, thereby diminishing its competitive advantage in a rapidly evolving sector.

Operational inefficiencies

Cost-cutting measures, particularly when applied to critical operations, can lead to inefficiencies. Reducing spending on equipment maintenance, for instance, can cause frequent breakdowns, disrupting production schedules and increasing long-term costs.

Similarly, cutting labor or outsourcing essential tasks may reduce productivity and compromise the quality of products or services. Instead of achieving savings, businesses might incur hidden costs from inefficient processes, delays, or increased waste.

Deteriorated customer experience

When businesses cut operating costs, areas such as customer service, product quality, and delivery processes are often impacted. Reducing customer service staff, for example, can lead to longer response times and frustrated customers.

Similarly, cost-cutting that affects product quality or delivery timelines can result in dissatisfied customers, reduced loyalty, and negative reviews. Over time, a decline in customer experience can harm revenue and damage the company’s reputation.

For instance, a retail business that lowers inventory management expenses might struggle to meet demand, leading to stockouts and dissatisfied shoppers.

Supply chain issues

Reductions in operating cost in business that target the supply chain can create significant disruptions.

Opting for cheaper suppliers to save money may result in lower-quality materials, delayed deliveries, or unreliable partnerships. Cutting transportation or logistics budgets can cause delays in shipments, increasing operational bottlenecks.

Additionally, reduced investments in supply chain monitoring and technology may weaken visibility and control, further complicating operations. Businesses that fail to prioritize a stable and efficient supply chain risk costly delays and a decline in product reliability.

Impaired employee morale

One of the most immediate risks of cutting operating costs in cost accounting is the negative impact on employee morale.

Reductions in salaries, benefits, or workforce can lead to job insecurity, stress, and dissatisfaction among employees. A demotivated workforce often results in decreased productivity, higher turnover rates, and lower overall performance.

For example, if a company eliminates training programs or employee incentives to save costs, it may struggle to retain skilled workers and foster a positive work environment. Long-term success depends on engaged and motivated employees, and short-sighted cost cuts can undermine this foundation.

Short-term focus

Excessive cost-cutting often prioritizes short-term financial gains over long-term sustainability. While reducing expenses might temporarily boost profits, it can harm the company’s growth prospects.

For instance, cutting marketing budgets may reduce costs in the short term, but it can also limit brand visibility and customer acquisition. Similarly, reducing investments in infrastructure, technology, or employee development can hinder the company’s ability to scale and adapt to market changes in the future.

Businesses must balance immediate savings with long-term strategic goals to remain competitive and sustainable.

Deteriorated brand image

Aggressive cost-cutting measures that affect product quality, customer service, or employee well-being can damage a company’s brand image.

Customers, employees, and stakeholders expect businesses to maintain a certain level of quality and consistency. If cost reductions lead to inferior products, poor service, or unethical practices, the brand’s reputation can suffer significantly.

For instance, a luxury brand that compromises on material quality to save costs risks losing customer trust and market position. Rebuilding a damaged brand image requires substantial time and investment, often far outweighing the initial cost savings.

Strategies for managing operating costs

Effectively managing the operating cost in business is vital for maintaining profitability, improving efficiency, and ensuring long-term business sustainability.

By adopting well-planned strategies, businesses can optimize their expenses without compromising the quality of their operations.

Below are ten key strategies to manage operating costs successfully.

1. Benchmarking

Benchmarking involves comparing a company’s operating expenses and performance metrics with industry standards or competitors. This analysis helps identify areas where the business may be overspending or underperforming. By recognizing inefficiencies, businesses can adopt proven strategies to optimize costs.

For instance, if competitors achieve similar outcomes with lower marketing expenses, this may highlight opportunities for process improvement. Benchmarking ensures businesses remain competitive by adopting best practices and identifying cost-saving opportunities.

2. Analyzing workforce requirements

Evaluating workforce requirements ensures that staffing levels align with the business's actual needs. Overstaffing can inflate payroll costs while understaffing may lead to delays and inefficiencies.

Regularly reviewing workloads, adopting flexible work arrangements, or streamlining operations can optimize labor utilization. Cross-training employees to handle multiple roles also improves adaptability and reduces the need for additional hires, enabling better management of labor-related expenses.

3. Re-negotiating supplier contracts

Suppliers significantly influence operating costs in cost accounting, especially for businesses reliant on raw materials or services. Renegotiating contracts with suppliers can lead to cost reductions, improved payment terms, or additional services at no extra charge.

Strengthening relationships with key suppliers may also unlock volume discounts or loyalty incentives. For instance, negotiating a long-term supply contract might result in predictable pricing and enhanced financial stability.

4. Conducting regular audits

Regular audits of operating costs help identify unnecessary expenses, inefficiencies, and potential savings opportunities. Audits provide a detailed understanding of how money is spent across different areas of the business, such as utilities, office supplies, and vendor payments.

For example, an audit might reveal overlapping software subscriptions or excessive energy consumption, enabling corrective actions to reduce costs. Periodic reviews ensure transparency and accountability in financial management.

5. Adopting just-in-time inventory system:

The just-in-time (JIT) inventory system minimizes inventory holding costs by aligning inventory levels with production schedules. Instead of maintaining large stockpiles, businesses receive materials and goods only when needed. This approach reduces warehousing expenses, spoilage, and obsolescence.

For example, a manufacturing business that adopts JIT can save on storage costs while maintaining a lean supply chain. However, successful implementation requires reliable suppliers and accurate demand forecasting.

6. Adopting sustainable energy measures

Implementing energy-efficient strategies can significantly reduce utility costs while promoting environmental stewardship.

Businesses can achieve this by adopting advanced, energy-saving technologies such as solar energy systems, smart thermostats, and energy management software designed to track and optimize energy use. Even simple adjustments, such as switching to LED lighting or installing motion-activated lights, can minimize energy waste.

Additionally, investing in energy-efficient equipment not only lowers operational expenses but also enhances reliability and productivity. To support these efforts, many governments and organizations offer financial incentives, such as tax and subsidies, making for businesses to sustainable energy solutions. initiatives pave the way for-term cost savings and a positive impact.

7. Automating repetitive tasks

Automation enables businesses to optimize their workflows by delegating repetitive, manual tasks to technology, thus reducing labor dependency and increasing efficiency.

Processes such as data entry, invoice generation, inventory tracking, and customer interactions can be automated using specialized tools or AI-driven systems.

For example, implementing chatbots for customer support ensures consistent, 24/7 service while freeing up employees for higher-priority tasks. In production environments, automated machinery can improve accuracy, reduce downtime, and enhance scalability.

While automation often requires an upfront investment, it delivers sustained cost savings, faster operations, and fewer errors, ultimately supporting the company’s long-term financial goals.

8. Adjust & review pricing

Operating costs directly influence pricing strategies. Regularly reviewing and adjusting prices ensures that revenue covers all expenses while maintaining competitive market positioning. Businesses should factor in changes to production costs, labor, and market demand when reevaluating prices.

For instance, if material costs increase significantly, adjusting product pricing helps maintain profitability without eroding margins. Transparent communication with customers about price changes can also preserve trust and loyalty.

9. Conducting cost-benefit analysis

Conducting a cost-benefit analysis when you calculate operating cost reductions helps evaluate the trade-offs between the expenses and benefits of specific initiatives.

For example, upgrading machinery might require a high upfront cost but could lead to increased efficiency, reduced maintenance expenses, and higher output in the long run.

Cost-benefit analysis allows businesses to prioritize investments that deliver the best returns, ensuring resources are allocated strategically and effectively.

10. Outsourcing

Outsourcing enables businesses to delegate non-core activities to external experts, thereby streamlining operations and reducing in-house costs. Tasks such as support, payroll processing, human resources management, and customer service are often more efficiently managed by specialized firms that offer expertise and economies of.

For example, outsourcing IT services to a dedicated provider ensures access to advanced technology and skilled professionals the need to maintain an expensive in-house team. By focusing internal resources on core, businesses can improve overall, reduce overhead, and enhance their ability to adapt to market demands.

Outsourcing is particularly beneficial for scaling businesses seeking cost-effectiveness without compromising quality or service delivery.

Relationship between operating costs and profit generation

Operating costs in cost accounting and profit generation are tightly intertwined, with the former playing a pivotal role in determining the financial health and sustainability of any business.

An efficient cost structure, strategic pricing, and careful management of expenses all contribute to maximizing profits while mitigating risks.

Let’s explore how key factors influence this dynamic.

Cost structure

The cost structure of a business serves as the backbone for analyzing operating expenses. It encompasses fixed costs, such as rent and employee wages, as well as variable costs, including raw materials and utility bills.

Striking a balance in the cost structure is crucial to covering essential expenses without burdening the organization. Fixed costs offer consistency, while variable costs provide the agility to adjust operations in response to demand fluctuations.

By pinpointing and streamlining cost drivers, businesses can allocate resources more efficiently, thereby enhancing their profit margins.

Net profit calculation

Net profit is the ultimate indicator of a business’s profitability, calculated by subtracting total expenses from total revenue.

Operating costs, which include production, administrative, and marketing expenses, are significant components in this calculation. Efficient management of these costs directly impacts the net profit figure.

For instance, a company that controls operating expenses without compromising quality or output will achieve higher profitability compared to one with inflated, unchecked costs.

Impact of sales and marketing expenses

Sales and marketing are essential for driving revenue, yet they also significantly contribute to operating costs.

Achieving a balance between investment in these areas and their returns is crucial. Over-investing in marketing without a corresponding increase in sales can erode profits while under-investing may hinder growth.

Businesses must assess the return on investment (ROI) of their marketing campaigns to ensure that every dollar spent contributes meaningfully to revenue generation.

Pricing strategy

An effective pricing strategy is crucial for managing operating costs and driving profitability. Businesses must set prices that are both competitive and sufficient to cover expenses while ensuring a healthy profit margin.

Adopting value-based pricing, which aligns prices with the perceived value offered to customers, often enables companies to achieve higher margins. Conversely, excessively low pricing can result in narrow profit margins, making it difficult to meet operating costs and sustain long-term business viability.

Break-even analysis

Break-even analysis is a vital tool for understanding the relationship between costs, pricing, and profitability. It determines the sales volume needed to cover total expenses, including both fixed and variable costs.

Reaching the break-even point signifies that a business is neither losing money nor generating profit; exceeding it marks the beginning of profit generation. This analysis is essential for setting realistic sales targets, making informed pricing decisions, and evaluating the financial feasibility of new ventures.

Adaptation to market changes

Market dynamics constantly evolve, and businesses that adapt to these changes can manage operating costs in cost accounting more effectively. For example, adopting new technologies or optimizing supply chain processes can reduce expenses while maintaining output quality.

Similarly, staying attuned to consumer preferences and adjusting product offerings accordingly can prevent unnecessary expenditures on obsolete or unpopular products. Flexibility and innovation help businesses remain competitive and cost-efficient, boosting profitability.

Sustainable profitability

Sustainable profitability is the goal of every business and is achieved by managing operating costs without compromising long-term growth. This involves investing in cost-efficient processes, embracing environmentally friendly practices, and building strong relationships with stakeholders.

For instance, using renewable energy sources or optimizing resource utilization not only reduces costs but also appeals to eco-conscious customers, fostering loyalty and brand reputation.

Scaling capacity

Scaling operations is a double-edged sword in terms of operating costs. While expansion increases revenue potential, it also raises expenses.

To achieve scalable profitability, businesses must ensure that growth-related costs, such as hiring additional staff or investing in new equipment, are proportionate to the anticipated revenue increase.

Economies of scale play a critical role here, as larger operations often lead to lower per-unit costs, improving overall profit margins.

Risk management

Managing risks associated with operating costs is crucial for sustained profit generation. Unforeseen expenses, such as supply chain disruptions or regulatory changes, can significantly impact profitability.

Implementing contingency plans, diversifying suppliers, and maintaining an emergency fund are effective strategies to mitigate such risks. Additionally, conducting regular financial audits helps identify inefficiencies and areas of cost leakage, enabling businesses to address issues proactively.

What are the key performance indicators to monitor your operating costs?

Effective cost management is essential for the profitability and sustainability of any business.

Key performance indicators (KPIs) provide valuable insights into how operating cost in business are managed, enabling businesses to identify inefficiencies and optimize processes.

Seven critical KPIs that help monitor and control operating costs include:

1. Operating expense ratio

The operating expense ratio (OER) measures operating expenses as a percentage of total revenue. It is calculated as:

OER = (Operating Expenses / Revenue) × 100

This KPI highlights how efficiently a company is managing its operational costs relative to its income. A lower OER indicates greater efficiency, as a smaller portion of revenue is being consumed by expenses.

For example, an OER of 20% implies that only 20% of revenue is spent on operating costs, leaving more room for profitability. Regular monitoring of this ratio helps businesses identify cost-saving opportunities and maintain financial stability.

2. Cost of Goods Sold (COGS)

COGS refers to the direct costs incurred in producing goods or delivering services, including materials and labor. It is a critical KPI because it directly impacts gross profit and overall profitability.

Businesses aim to minimize COGS without compromising quality to maximize profit margins. Efficient inventory management, supplier negotiations, and process optimization can reduce COGS, making this KPI an essential metric for evaluating cost management.

3. Gross profit margin

Gross profit margin measures the percentage of revenue retained after covering the cost of goods sold (COGS):

Gross Profit Margin = [(Revenue - COGS) / Revenue] × 100

When evaluating operating cost formula calculations, this KPI evaluates how efficiently a company manages its production or service delivery costs compared to its earnings. A higher gross profit margin signifies strong cost control and effective pricing strategies.

For instance, retaining 60% of revenue as gross profit means the business has substantial funds available for other operating expenses and profit accumulation after meeting direct costs.

4. Net profit margin

Net profit margin is a comprehensive measure of profitability, indicating how much of each dollar of revenue remains as profit after covering all expenses, including operating costs, taxes, and interest:

Net Profit Margin = (Net Profit / Revenue) × 100

This KPI is vital for assessing the overall financial health of a business. A low net profit margin suggests that operating costs may be too high relative to revenue, signaling a need for cost optimization or revenue growth strategies.

5. Inventory turnover ratio

The inventory turnover ratio measures how efficiently a business manages its inventory by showing how many times inventory is sold and replaced over a specific period:

Inventory Turnover Ratio = Cost of Goods Sold / Average Inventory

A higher turnover ratio indicates efficient inventory management, reducing the risk of overstocking or obsolescence. Low turnover, on the other hand, may point to excess inventory, leading to higher holding costs and tying up capital unnecessarily.

Optimizing inventory turnover helps lower operating costs while ensuring adequate stock levels to meet demand.

6. Budget variance ratio

The budget variance ratio compares actual operating expenses to the budgeted amounts:

Budget Variance Ratio = [(Actual Costs - Budgeted Costs) / Budgeted Costs] × 100

This KPI helps businesses identify discrepancies between planned and actual spending. A positive variance indicates overspending, which can erode profitability, while a negative variance suggests cost savings.

Regular analysis of budget variance encourages accountability and allows businesses to adjust spending to stay on track financially.

7. Return on assets

Return on assets (ROA) gauges how well a company utilizes its assets to generate profits:

ROA = (Net Income / Total Assets) × 100

This metric reflects the efficiency with which a business leverages its resources to produce earnings. A lower ROA may suggest inefficiencies or underutilized resources, while a higher ROA indicates that the company is maximizing the value of its assets.

Tracking ROA regularly helps businesses pinpoint performance gaps and enhance their asset management to drive profitability.

Best practices for managing operating costs

Operating costs play a significant role in determining a company’s profitability and long-term sustainability. Managing these costs effectively requires a combination of strategic planning, real-time monitoring, and a thorough understanding of financial operations.

Below are some best practices businesses can adopt to optimize their operating costs while maintaining efficiency and productivity.

Incentivize employee engagement

Engaged employees are more likely to contribute to cost-saving initiatives and improve operational efficiency. Incentivizing staff to identify inefficiencies and suggest improvements can lead to innovative cost-reduction strategies.

For example, offering rewards for ideas that lower energy consumption or streamline workflows encourages employees to take ownership of the company’s financial health. This proactive involvement fosters a culture of accountability and continuous improvement.

Monitor your costs regularly

Regularly reviewing operating costs in cost accounting ensures that expenses stay within budget and helps identify potential overspending early.

Weekly or monthly assessments of cost categories, such as utilities, supplies, and labor, provide clarity on where funds are being allocated. This practice enables businesses to make timely adjustments, preventing minor inefficiencies from escalating into significant financial issues.

Renegotiate with vendors & suppliers

Reassessing agreements with vendors and suppliers is a key strategy for reducing costs. By initiating regular discussions, businesses can explore options for improved pricing, bulk purchase discounts, or more favorable payment terms.

These renegotiations can also uncover opportunities for additional perks, such as expedited shipping or extended product warranties, which enhance value without increasing expenses.

It’s equally important to periodically evaluate alternative suppliers to ensure competitive rates and quality standards are being met. Strengthening relationships with vendors while actively managing contracts helps businesses minimize procurement costs and maintain efficient operations.

Prioritize expenses based on contribution

Not all expenses contribute equally to a company’s revenue or growth. Prioritizing costs that directly impact productivity, customer satisfaction, or profit margins ensures optimal allocation of resources.

For instance, investing in tools that enhance operational efficiency or improve product quality can deliver higher returns compared to spending on non-essential areas. By focusing on high-impact expenses, businesses can allocate funds more strategically and manage operating cost in business effectively.

Encourage cross-departmental collaboration

Collaboration between departments can uncover opportunities for cost reduction and process optimization. Sharing resources, standardizing procedures, and consolidating tasks reduce redundancy and streamline workflows.

For example, a marketing team coordinating with sales can avoid duplicate efforts and maximize the impact of campaigns. Cross-departmental collaboration fosters a unified approach to managing operating costs efficiently.

Set up an expense management system

An expense management system provides transparency and control over business spending. These systems help track expenditures, set spending limits, and streamline reimbursement processes.

Automation reduces manual errors and enhances compliance with company policies. By implementing such a system, businesses can gain better visibility into their expenses and identify areas for cost reduction.

Incorporate real-time monitoring tools

Real-time monitoring tools allow businesses to track expenses and financial performance as they occur. Tools that provide real-time data, such as cloud-based accounting software or expense-tracking apps, enable quick decision-making.

These tools also generate insights into spending patterns, helping businesses identify trends and potential inefficiencies early.

Develop a detailed budget

A detailed budget serves as a financial blueprint, outlining expected expenses and income across all operational areas. It helps businesses allocate resources effectively, ensuring that funds are directed toward high-priority activities while avoiding unnecessary spending.

A good budget incorporates specific expense categories, projected revenue, and contingency plans for unforeseen costs. It also establishes spending limits for various departments, creating accountability and fostering financial discipline.

Developing such a comprehensive budget enables businesses to monitor their financial health, make informed decisions, and stay aligned with their long-term goals.

Review & revise budgets periodically

Markets, operations, and business needs evolve, making it essential to review budgets periodically. Regularly assessing and revising the budget ensures that it reflects current conditions and business priorities.

For instance, unforeseen costs, such as inflation or supply chain disruptions, may require reallocating funds to maintain operational efficiency. Frequent budget reviews help businesses remain agile and responsive to changing circumstances.

Conduct industry benchmarking

Benchmarking involves comparing your operating costs and performance metrics to industry standards or competitors. This practice identifies areas where your business may be overspending or underperforming.

For example, if your utility costs are higher than industry norms, exploring energy-efficient alternatives could yield savings. Benchmarking provides valuable insights into optimizing costs and improving overall efficiency.

Ensure an in-depth understanding of your costs

A comprehensive understanding of all operating costs in cost accounting is critical for effective management. Businesses should break down expenses into categories, such as fixed and variable costs, and analyze each in detail.

Understanding the underlying drivers of costs enables businesses to implement targeted strategies to reduce unnecessary expenditures. For instance, identifying high shipping costs may prompt a review of logistics partners, leading to more cost-effective solutions.

Monitor essential KPIs

Key performance indicators (KPIs) provide measurable insights into how effectively operating costs are being managed. Metrics such as operating expense ratio, cost of goods sold, and gross profit margin reveal areas of inefficiency and guide decision-making.

Regularly monitoring these KPIs ensures that costs remain aligned with revenue goals and helps identify trends that could impact profitability.

Technological advancements in managing your operating costs

Technological innovations have transformed the way businesses manage operating costs, enabling greater efficiency and cost control.

Tools like data analytics, cloud computing, corporate cards, and expense management software empower companies to optimize their spending and improve financial decision-making.

Data analytics

Data analytics provides valuable insights into patterns of spending, cost drivers, and inefficiencies. By analyzing real-time as well as past performance data, businesses can identify areas of excessive or unnecessary expenditure and implement targeted measures to boost cost savings.

Predictive analytics further aids in forecasting future costs and trends, allowing companies to make proactive financial decisions. This data-driven approach enhances accuracy, reduces waste, and supports strategic planning when managing operating cost in business.

Cloud computing

Cloud computing reduces operating costs related to IT by eliminating the need for both expensive on-premises infrastructure and hardware. With the help of solutions that are scalable, businesses can pay only for the resources they use, avoiding unnecessary expenses.

Additionally, cloud-based platforms enhance collaboration and streamline processes, reducing the time and effort required to manage operations. The ability to access data remotely also improves decision-making and operational flexibility.

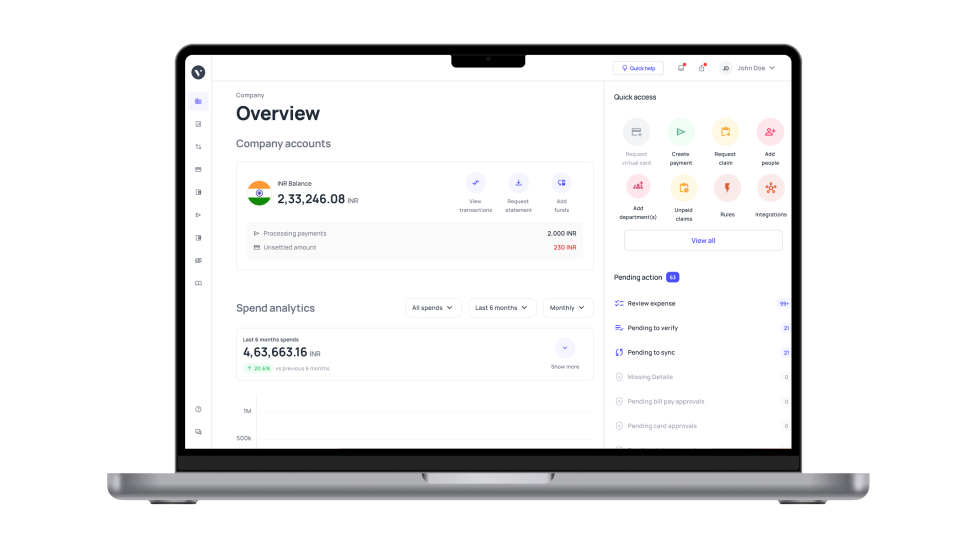

Corporate cards

Corporate cards simplify expense tracking and provide real-time visibility into business spending. By offering pre-set spending limits and category restrictions, these cards prevent overspending and ensure compliance with company policies.

Furthermore, automated reporting features reduce administrative work, saving time and lowering labor costs. Corporate cards also offer rewards programs, such as cashback or discounts, further optimizing costs.

Expense management software

Expense management software automates the tracking, approval, and reporting of business expenses. These tools integrate with other financial systems to ensure accurate data and provide detailed insights into spending habits.

Features like policy enforcement, receipt capture, and real-time alerts streamline processes and reduce manual errors, enabling businesses to control operating cost in business effectively.

How does an expense management software help in managing your operating costs?

Expense management software is an effective tool for streamlining the tracking, controlling, and optimization of business expenditures.